Tech Innovation Drives OB Production To Sustainable Future

The Ross Video Ultrix Hyperconverged platform delivers high-end productions while cutting weight, fuel and carbon footprint

Achieving sustainability targets is becoming a major consideration for Outside Broadcast facilities providers in Europe and will likely weigh heavily in the thinking of OB companies around the world as government regulators adopt measures to reduce carbon emissions.

For OB companies, compliance is a heavy lift. On one hand, they must satisfy all of the production requirements of their clients—something that’s heavily dependent upon what technology is on board. On the other hand, OB facilities providers face penalties or even worse for not complying with sustainability targets when it comes to vehicle weight.

Until recently, there hasn’t been a suitable alternative to business-as-usual remote production. Large, expando tractor trailers, essentially TV production studios on wheels, have required lots of technology, signal routing and remote power.

However, that’s all changed thanks to the Ross Video Ultrix hyperconverged production platform. Ultrix combines production switching, audio mixing, multi-viewers, video and audio routing, color correction, signal processing, audio embedding and de-embedding and frame synchronization in a single platform, thus the term “hyperconverged.”

This means weight is dramatically lower; less rack space is needed; fewer cables are necessary, and required on-site power is far less.

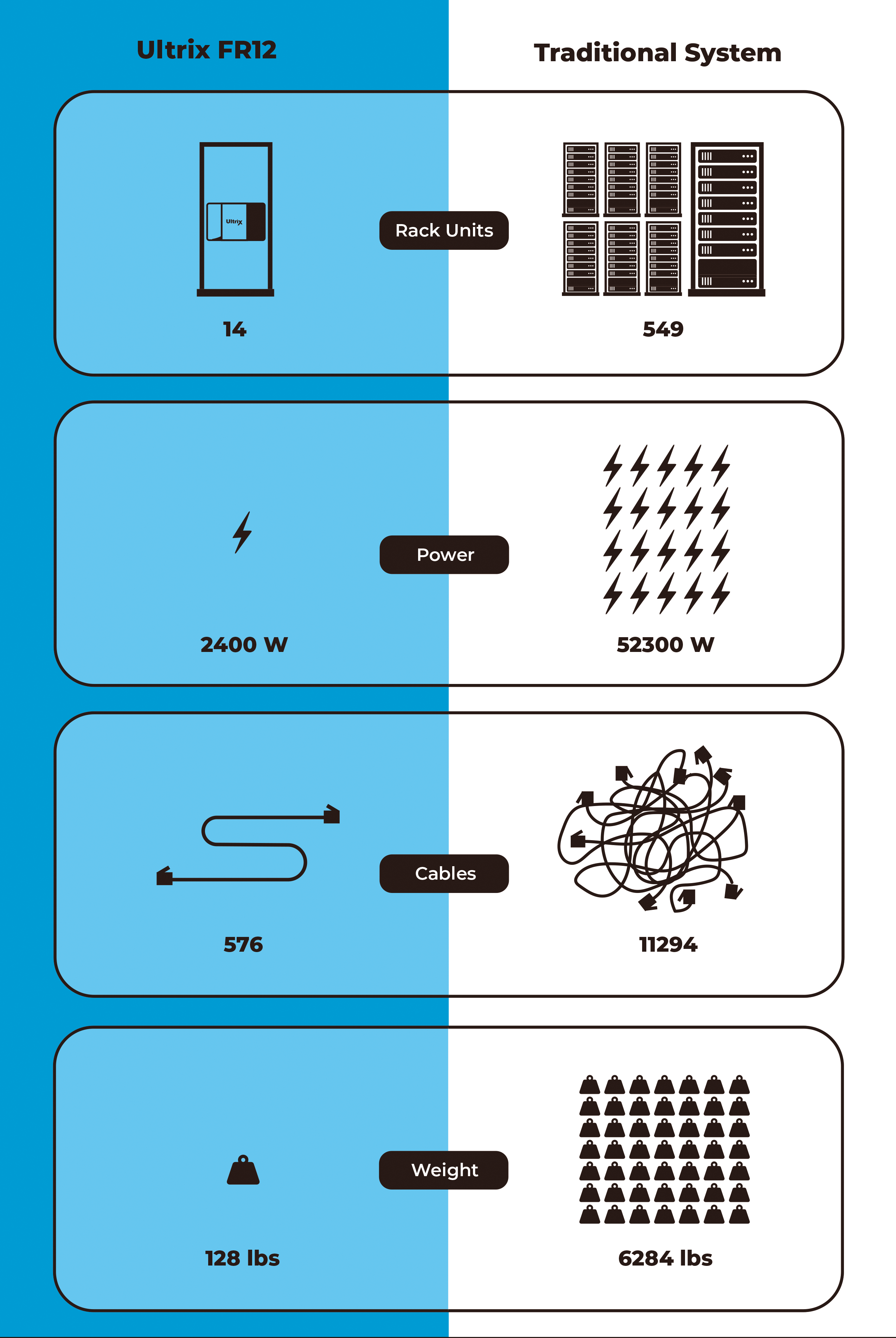

By way of comparison, consider an Ultrix FR12 Hyperconverged production platform and a traditional OB trailer decked out with the same production capabilities. The Ultrix FR12 delivers and same production punch in 14 rack units vs.as what would take a row or even multiple rows of full racks in a traditional system.

Power savings are huge, too. An OB vehicle would require significant amounts of power to do what the Ultrix FR12 can do with only 2,400W. There are big savings in terms of cables as well: thousands of interconnect cables for a traditional unit vs. a few hundred cables for the Ultrix FR12.

The professional video industry's #1 source for news, trends and product and tech information. Sign up below.

All of this adds up to a huge weight difference. In a traditional OB trailer, thousands of pounds of technology, racks and cables would be required to deliver the same production capabilities as an Ultrix FR12 setup weighing just 128 pounds.

Smaller, lighter production trucks made possible by Ultrix burn less fuel than their heavier counterparts and therefore have a smaller carbon footprint. They are also becoming increasingly important in Europe as countries place weight restrictions on commercial vehicles traversing city centers—precisely where many broadcast sporting and entertainment events occur.

While weight savings, reduced fuel usage and lower on-site power requirement are significant in the context of sustainability for OB facilities providers, they are equally as important when it comes to production flypacks.

The weight savings of Ultrix alone are significant because lighter flypacks cost less to ship. Beyond these savings, Ultrix-centric flypacks mean setup, maintenance and teardown are far easier and less time-consuming simply because there are fewer discrete tech components in the system. And regardless of whether it’s an OB truck or a flypack, ease of deployment and use translates directly into easier management and ultimately higher profitability.

Keeping It Simple

The desire to boost profits where possible has driven a movement among OB facilities companies towards simplification. The simpler things are, the less effort ultimately required to bill for OB facilities and flypacks.

The effect of the Ultrix Hyperconverged production platform on simplification is far-reaching. Before a new production truck or trailer is even built, the availability of a hyperconverged production platform simplifies design, reducing equipment room space and cooling load as well as drastically cutting the number of cable runs otherwise required.

From an operational perspective, Ultrix simplifies operations and engineering as well as personnel training. Not only do fewer discrete pieces of technology make Ultrix simpler to use and maintain than a traditional production setup, but having one system do so much in software means system training is simpler.

With many OB facilities providers reporting problems with higher-than-normal turnover, easier training makes managing frequent personnel departures simpler to handle by reducing the time and effort necessary to bring new hires up to speed.

Having common control over so many functions, Ultrix also simplifies configuration, monitoring and troubleshooting and potentially reduces the number of personnel needed to staff any given production.

The Ross Video Ultrix Hyperconverged production platform is enabling today’s OB facilities providers and others to succeed in a changing landscape of environmental impact concerns, staffing and personnel demands and operational realities.

Consolidating what previously were multiple discrete production technologies into the compact, lightweight and power-efficient platform that is Ultrix makes achieving sustainability requirements possible—something that’s a must-have in Europe and soon will likely be required around the world.

But simply baking so many diverse production capabilities into a single system isn’t enough. In the high-stakes game of television production of sporting and entertainment events, delivering superior video and audio quality is table stakes. Here too, Ultrix excels.

For all of these reasons, many OB facilities providers in Europe and elsewhere where sustainability is a top priority are specifying Ultrix for their new OB vehicles and in the process are positioning themselves for future success.