When Does Fiber Make Sense?

High bit-rate 1080p and 3D video signals are stressing the limits for coaxial cable, even inside the studio. Fiber optic systems offer clean transmission outside a studio, and cost reductions have made them increasingly suitable for use inside a production facility. While coax may always be the best choice for short distances, fiber is clearly preferable for long connections. So the question becomes: at what distance does it make sense to trade the cost advantages of coax for the performance advantages of fiber? There is no single answer, but some general guidelines can be defined.

DISTANCE LIMITATIONS

Any signals flowing through a conductor will be attenuated, whether the cable is made of glass or copper. If too much attenuation is present, the receiver will not be able to recover the signal.

In fiber systems, losses amount to fractions of a dB per kilometer. Even inexpensive digital transmitters will have an optical loss budget of more than 10 dB. With fiber loss less than 0.5 dB per kilometer, a single link can easily reach 20 km. Many systems offer ranges of 100 km or more. Clearly, cable loss is not an issue for fiber optics inside a studio.

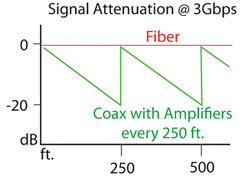

Fig. 1: Comparison of 3 Gbps signal losses over fiber optic and Belden 1694A coaxial cable The situation is quite different for coaxial cable. Depending on the data rate and the type of cable, a signal can be attenuated to the point that it needs to be regenerated in less than 100 meters. According to Belden, a 3 Gbps SMPTE 424M signal is attenuated by 20 dB in just 250 feet in 1694A, a cable commonly used in video applications. For longer distances, an amplifier (possibly with re-clocking) is needed to make up losses. Fig. 1 shows the comparison of cable losses for fiber and coax, assuming a repeater every 250 feet for the coax signal.

OPTICAL TRANSCEIVERS

Most video devices are designed for electrical I/O, as they need to input or output signals via BNC connectors, which are relatively low in cost.

When optical signal paths are used, electrical to optical (E/O) and optical to electrical (O/E) converters are required at each interface. These can be embedded directly in the video device. Alternatively, external converter modules can be used.

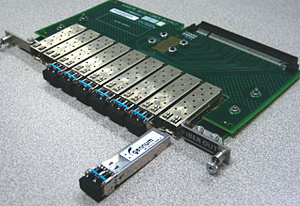

Some manufacturers use a technology called SFPs (Small Form-factor Pluggable) devices, which require a mounting cage inside the equipment, which is then populated with a plug-in optical device. Fig. 2 shows a board equipped with an SFP cage and a plug-in SFP module. This allows devices to be sold without optical connectivity and upgraded with SFPs.

FIBER VS. COAX COSTS

Raw coax and fiber cable costs are roughly the same. Single conductor cables of both types can be purchased for less than 50 cents per foot. Connectors can be pre-installed or field-applied for either technology. A skilled technician can apply crimp-on fiber or coax connectors in roughly the same amount of time. Fiber connectors cost 10 times as much as coax connectors, but this cost is small relative to the other system components.

The big cost difference between the two is due to the cost of E/O and O/E transceivers. For 1.5 Gbps signals, standalone modules are available for less than $1,000 per end. For 3 Gbps links, prices are somewhat higher, ranging up to $2,000 per end. Michel Proulx of Miranda indicated that SFP-based connections are 60 to 70 percent lower than standalone modules for 3 Gbps paths.

One difference between fiber and coax is size and weight, especially when multi-fiber cables are used. A cable with 96 optical fibers is less than one inch in diameter and weighs 0.3 pounds per foot. The same number of coaxial conductors would have a cross section of almost three inches and weigh 4.3 pounds per foot. This would have to be taken into account in planning cable trays and other infrastructure items.

Another difference is upgradeability. Single-mode fiber has essentially unlimited bandwidth and can handle dozens of 10 Gbps signals using multiple wavelengths. Once fiber is installed, it can be reused by changing the devices at each end. Coax linkage is harder to upgrade, particularly if mid-span amplifiers are used.

One factor that doesn't have big impact on video signals is crosstalk between cables. Unlike data cables that use unshielded twisted pair, coax signals are well shielded, and don't create much interference between adjacent cables. According to Belden's Steve Lampen, shielding provides isolation between adjacent coaxial cables greater than 100 dB, which is certainly enough to prevent interference.

FROM THE EXPERTS

Fig. 2: Fiber optic interface board, showing one SFP removed from its cage. ©Miranda Technologies Opinions in the industry vary widely about when to use fiber or coax.

"Every time you use coax you're crossing your fingers," said Rich Cerny of Telecast Fiber Systems.

He pointed out the potential for copper corrosion to impact signal flow, and also the difficulties in preventing ground loops or other unwanted signal flows. Cerny's recommendation is to use fiber for any runs longer than 10 meters.

Dave Anderson of The Switch has designed his facilities to hold cable runs between devices to less than 100 feet, and rarely employs fiber within a facility. However, he is a big fan of fiber optic technology for connections to telecom carriers and outside customers.

Jim Jachetta of Multidyne expressed his concern about environmental factors limiting the distance of coaxial installations. This includes interference from outside devices such as HVAC motors and lighting equipment. He indicated that coax systems that operate at 1,000 feet in the developmental laboratory might not work in real world applications.

In contrast, Belden's Lampen says that 250-foot repeater spacing is quite conservative. With modern cable drivers and receivers, longer distances between repeaters can be attained with good results.

WHICH TO CHOOSE?

So where does this leave the studio facilities engineer? For short connections (a few feet) coax is preferred—there are no measurable performance benefits with fiber in such instances, and the associated costs are lower with coax. Longer runs between racks in the same rack lineup may also be easier with coax.

For longer connections between different areas of the studio, across aisles or between floors, fiber's benefits may justify the extra expense. The combination of lower losses, smaller cables, future-proofing and elimination of repeaters or amplifiers become compelling for 3 Gbps signals at distances much greater than 300 feet.

For installations that involve significant installation costs, such as runs that transition between floors or through building firewalls, engineers may want to consider fiber optic linkage to provide an upgrade path when signal rates increase further.

Wes Simpson is an industry consultant and author of "Video Over IP, Second Edition," from Focal Press.

Get the TV Tech Newsletter

The professional video industry's #1 source for news, trends and product and tech information. Sign up below.

Wes Simpson is President of Telecom Product Consulting, an independent consulting firm that focuses on video and telecommunications products. He has 30 years experience in the design, development and marketing of products for telecommunication applications. He is a frequent speaker at industry events such as IBC, NAB and VidTrans and is author of the book Video Over IP and a frequent contributor to TV Tech. Wes is a founding member of the Video Services Forum.