San Bernardino combines two local broadcasting operations

California’s San Bernardino Valley, just east of Los Angeles, has long been underserved in local broadcasting. Surpassing three million in population, the region is considered part of the number-two Los Angeles television market and, for many years, has received its news and local programming from the city.

The upper floor of the City of San Bernardino Telecommunications Facility is dedicated to the ICTN news operation. In the news-control console, a ParkerVision PVTV CR16 production automation system allows ICTN to produce a large-market level newscast using a minimal production crew by automating all aspects of a legacy production.

In response to the need for a locally originated newscast aimed at regional viewers, California State University of San Bernardino last year directed $1.2 million in federal funding toward the purchase of digital equipment. This funding led to the development of the City of San Bernardino telecommunications production facility, a highly automated, multichannel SDI facility that offers up to four simultaneous program streams. The university contracted Digital System Technology (DST) to design and integrate the multichannel facility.

The facility is home to two organizations: The Inland California Television Network (ICTN) and KCSB-TV. ICTN is a new network founded to produce and cablecast local news for the San Bernardino Valley. KCSB-TV is an established local network that broadcasts educational, public and government-access programming. The facility’s headend links 15 municipal-government channels. At 10 p.m. every day, all 15 channels switch from local public-interest programming to carry ICTN’s half-hour newscast.

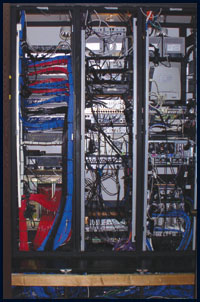

Production control on the lower floor is generally used for KCSB-TV productions but also serves as a backup to the ICTN news operation upstairs. A Ross Synergy One production switcher and an Ikegami monitor are among the visible components in this photo.

Upstairs, downstairs

DST pre-built the equipment racks for the two-floor facility off-site, employing its patented “palletization” method for a smoother integration process. The facility has small elevators, so DST integrated the equipment and consoles designated for the upper floor as individual racks.

Get the TV Tech Newsletter

The professional video industry's #1 source for news, trends and product and tech information. Sign up below.

From an engineering standpoint, the project was straightforward. But DST faced some challenges stemming from the facility’s government-based funding. Changes in some equipment specifications resulted in engineering challenges during the integration process. Nonetheless, with great assistance from chief engineer Klyde Layon, DST met these challenges and prepared the facility for system upgrades well into the future.

Upstairs

The upper floor is dedicated to the ICTN news operation and features a studio, a newsroom area and a control room. For live news production, ICTN uses a ParkerVision PVTV CR16 production automation system. The ParkerVision system automates all aspects of a traditional newsroom, including the switcher, audio and graphics. PVTV allows ICTN to produce a large-market-level newscast using a minimal production crew.

The news staff programs the entire 10 p.m. newscast into PVTV prior to air and produces it using the system’s Windows-based graphical user interface. The system features 16 inputs to integrate additional gear, including three ParkerVision Digital CameraMan cameras in the news studio and a SHOT Director multi-camera control system. An Avid iNEWS system integrates scripts from the news rundown into the PVTV system.

Editors prepare story edits on an Avid NewsCutter XP nonlinear editing system and store them on a 360 Systems Image Server 2000 playout server. PVTV then calls for the appropriate clip as designated on the system’s news rundown.

All feeds from KCSB-TV and ICTN go through master control before leaving the building. A Blueline Automation Suite is central to the multichannel master-control operation and communicates with Blueline video servers to ingest and recall on-air programming. Two master control racks next to the console are home to monitors and tape machines for recording and duplication.

The integration team chose the Image Server 2000, with 48 hours of storage, three playback channels and one channel of record, because of its low price and because, during previous testing, it had proven its ability to interface with PVTV. Image Server 2000’s support of the MXF format allows ICTN to eventually transfer data files from the facility’s shared network storage system (Avid LANshare EX) to an Image Server 2000, creating a completely tapeless newsflow. For now, the news staff shoots with JVC’s Pro DV GY-DV5000 using Mini DV as its tape format, but is looking forward to adding a JVC DR-DV5000 hard-drive solution to its cameras. A 360 Systems DigiCart provides additional live news production effects.

Three equipment racks of ParkerVision gear are integrated near the news control-room desk console, along with a mixed Ikegami and JVC monitoring wall. The ParkerVision equipment connects to other production sources on the first floor, including a Chyron Duet character generator and a Spencer Technology Newstore system, which is used to integrate stills and animation sources for over-the-shoulder boxes.

Downstairs

The lower floor is home to the cable headend transmission facility that links the 15 municipal stations. Several areas shared between the ICTN network and KCSB flesh out the main floor: master control, terminal gear, production control, a production studio, and two editing bays.

Master control and the terminal-gear area share space within a long, narrow (about 7-foot wide) corridor. Master control is a fairly simple operation. It transmits four automated standard-definition channels through Ross CDK111 downstream keyer for bug insertion and then on to the cable headend. A console built by Laguna Design houses a Blueline Automation Suite to create playlists and to ingest programming into two Blueline video servers.

DST simplified maintenance procedures for the engineering team by adding rear access doors to all terminal gear equipment racks and built doors into a production studio wall behind the terminal-gear area. This allows engineers to access those racks through the production studio instead of pulling the racks out from the wall.

The Blueline Automation Suite, combined with two BlueMPEG video servers, are central to the facility’s multichannel broadcast operation. The automation equipment controls all relevant equipment and play-to-air feeds, minimizing manual operation in master control. Four SDI encoded streams ingest programming from satellite or tape into BlueMPEG; four SDI or analog playout streams are used to play to air. The playout streams account for most on-air programming, except for news, direct-to-air satellite feeds and other live in-house productions. Automated playout streams are scheduled for the appropriate on-air output channel using BlueMPEG.

A 7TB DVD jukebox archival system from DISC-Storage Systems provides long-term storage. The Blueline Automation Suite communicates with the DVD jukebox to recall long-term programming when needed. A network-attached storage (NAS) solution provides short-term storage (less than one week’s worth).

The Blueline Automation Suite comprises several software application packages divided among five computers. AirStation recalls programming to air from the BlueMPEG2 video server, while two additional computers ingest and play out. (The fifth computer, PrepStation, is installed upstairs for traffic purposes.) All Blueline systems are mirrored and redundant; if the AirStation computer fails, AirStation capabilities can be performed on the PrepStation computer.

Rounding out master control are several JVC D9 tape machines for duplication and recording. They can also be used for on-air redundancy, automated or manual, depending on the degree of equipment failure. Master control can also connect to the Spencer Technology Newstore system in production control, using its built-in DVE capabilities to create squeezebacks during credits.

DST simplified maintenance procedures for the engineering team by adding rear access doors to all terminal gear equipment racks and built doors into a production studio wall behind the terminal-gear area. This allows engineers to access those racks through the production studio instead of pulling the racks out from the wall.

The terminal-gear area is built on an access floor 12 inches above master control. Equipment racks here house electronics for all facility equipment except for some news-control systems. A Ross Talia 40x32 routing system handles video and audio source distribution throughout the facility; the system is expandable to 64x64 as new sources are added. Leitch DPS575 frame synchronizers and Scientific-Atlanta and Motorola satellite receivers fill out the terminal-gear racks to process incoming satellite feeds. Those feeds are then recorded to Blueline or played directly to air off the receivers. Minimal physical space was the biggest integration challenge in this area. DST installed rear doors on the equipment racks for system maintenance. Engineers can access these racks through doors installed in the production studio, located directly behind the terminal-gear area. The master-control console pulls out from the wall for maintenance access.

A sliding glass door separates production control from the terminal-gear area. A Mackie digital audio mixer with support hardware is central to the audio operation, located within a booth on the right side of the room. A window in front of the Mackie board looks directly toward the production control console, built by Laguna Designs. A Ross Synergy One production switcher sits atop the console, along with a Chyron Duet character generator, SpencerTech Newstore for DVR capabilities, JVC D9 tape machines and Thomson OCP42 camera-control units. The ICTN network-news operation upstairs and various cable productions downstairs share many of these systems.

A monitoring wall sits above the console displaying the status of various video feeds. Multiple Ikegami 9-inch black-and-white monitors and JVC color monitors are arranged on adjustable shelving for reconfiguration. The Ikegami monitors are for confidence monitoring; the JVC color monitors are for critical signal monitoring. A TSL under-monitor display system tracks the monitor feeds.

The 4000-square-foot production studio is large for a cable-television facility, with three new Thomson 1707 cameras sitting on Vinten Pro-Ped pedestals and heads. This studio adds a redundancy layer for news control. If the ParkerVision system were to fail, the ICTN staff could produce the news manually between the studio and production control. KCSB and ICTN will produce locally originated programming from this studio. Both entities also produce contract-for-services work, including infomercials and marketing videos. The studio is also available for rent to independent producers.

The downstairs editing bays feature Avid Xpress DV nonlinear systems, which also tie to the Avid LANShare EX system and its 3TB of storage. LANShare EX can accommodate 20 users, and an external switch divides that number evenly between floors — 10 upstairs, 10 downstairs. This setup allows the production and news departments to share content.

One path to and from each editing area connects to the Ross Talia routing system, so edits done through the Avid systems can be ingested into the BlueMPEG video servers. Firewire patchbays were installed to connect between all facility editing bays. An operator in one edit bay requiring a tape machine in another bay can patch between the different systems.

Making the connection

All facility wiring is Belden 1505. Conduit runs were installed to connect systems between floors. Wiring for both the production control room and terminal-gear equipment is located under access floors, and that wiring feeds directly into the master-control console. A path from there feeds into the news control-room equipment upstairs. All wiring is HD-capable for future expansion.

Four cable-company-supplied modulators multiplex the separate broadcast signals as they leave the building. The multichannel signals go through the Ross CDK111 downstream keyers out of master control and into Videotek 12x1 analog switchers to provide backup signals in the event of router failure. Those signals then go into the cable headend modulators.

With the Inland California Television Network and KCSB co-located in the same facility, it was important to connect sources throughout the facility to allow both operations to share equipment. The openness of the facility and sense of inter-communication, along with future upgrade paths for a tapeless newsflow and high-definition television, create a future-ready cable television system that positions the City of San Bernardino telecommunications production facility well for the future.

Jeff Muhleman is vice president of contracts at Digital System Technology.