CMOS, 10 years later

SEATTLE—Ten years ago this writer returned from the NAB Show having seen JVC and Ikegami introduce CMOS-based cameras.

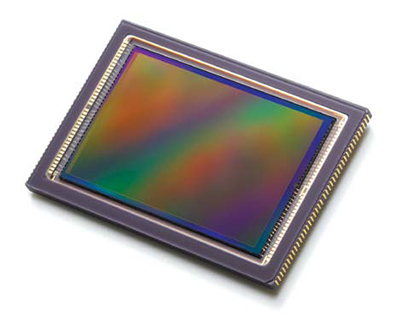

In my story in TV Technology at the time, “CMOS: New Imager on the Block,” no one interviewed suggested that the reigning video imager type at the time, charge-coupled devices (CCD) were soon to be relegated to the museum shelves, along with tube-based imagers. Complementary metal-oxide- semiconductors (CMOS) at that time held a great deal of promise, but were not yet ready for primetime.

Fast forward to the present and CMOS sensors have hit their stride as co-equals to CCDs, and have become the only choice in large-format, single-sensor cameras.

‘BUCKET BRIGADE’

Invention of CMOS technology actually preceded that of CCDs, but at that time, in the 1960s, manufacturing processes were not up to the task of producing such CMOS sensors. “It was determined early-on that CCD was an easier-to-realize technology,” said Klaus Weber, director of Imaging Technology at Grass Valley. “But since then, manufacturing processes have been dramatically improved, especially over the past 10 years. We now have the capability to produce CMOS imagers in very high quality, which is now exceeding CCD technology.”

Chuck Westfall, technical advisor for the Professional Engineering & Solutions Division at Canon U.S.A. Inc., pointed out that one clear advantage CMOS sensors enjoy over CCDs is that “the amount of time it takes to get data off the chip is much in CMOS’s favor.”’

While a technical description of the difference between that aspect of the two technologies is a story in itself, Westfall describes the process in a CCD as a “bucket brigade.” Where CCDs can be built with a maximum of two channels or paths to pass data off the imager, the higher-end CMOS sensors “tend to have either an 8-channel readout or even a 12- or 16-channel readout.” He said that particularly favors CMOS for use in single sensor cameras, where that single chip is called upon to capture color information that would be supplied from three different sensors in a 3-chip designed camera.

Get the TV Tech Newsletter

The professional video industry's #1 source for news, trends and product and tech information. Sign up below.

The speed with which data from a CMOS sensor can be transferred is one of the reasons that very high-speed cameras are designed with CMOS imagers.

Multiformat camera designs are another place where CMOS technology shines, according to Edgar Shane, JVC general manager of product engineering. “You can have the same sensor read interlaced or progressive format, and you can also read it at different resolutions,” he said.

“CCDs were pretty much specifically designed for specific formats… CMOS is very much universal,” he said. And by rebooting a CMOS camera each time the format is changed, “every single clock is regenerated, so you’re truly reading your sensor at that particular frame rate.”

Alan Keil, Ikegami’s director of engineering thinks CMOS has passed CCD technology at this point. “The performance is better in every way,” he said. “We would say now that CMOS has a little leg up on the best CCD in terms of raw performance, more performance in terms of sensitivity and signal to noise. You also look to modulation, which is better than CCDs. And [when] you look at dynamic range, it’s better than CCDs.”

PROS AND CONS

As the video camera industry moves forward to higher resolutions and perhaps larger imaging chips, another of CMOS’s advantages comes to light: power consumption. “As the size of the sensor increases,” said Canon’s Westfall, “then the amount of power it takes to run a CCD sensor really starts to ramp up. For example, when you get to a full-frame, 35mm sensor… then the CMOS sensor uses only about 1/100th of the power that the same size CCD would take to operate.”

At the 2013 NAB show, Ikegami and ARRI introduced the HDK-97ARRI broadcast-style production camera, built around ARRI’s Super 35mm CMOS sensor. One difference between CMOS and CCD technology where CCDs may be said to hold an advantage is in the CCD’s global shutter design, versus CMOS’s rolling shutter. A global shutter captures the entire image at once, then reads that information off the chip. The rolling shutter scans the pixels of the chip over time. When shooting fast action, this difference in the time when a particular part of the image was scanned can be deemed a disadvantage, especially when the video played back is stilled.

Sony and Grass Valley have introduced global shutter technology in some of their CMOS cameras, and others are expected to follow suit.

Ikegami’s Keil points out that when moving, rather than stilled video is played back on a monitor, the rolling shutter may actually be seen as an advantage. Since display devices themselves are “putting the video up line by line… I think there’s a slight advantage to CMOS’s line-by-line readout. It’s just temporally a better match.”

Nobody expects CMOS technology to stand still. “We continue to look for a variety of improvements,” said Keil. “Dynamic range is one area we’re trying to improve right now.” Others noted increased sensitivity as a target.

CMOS sensors employ video processing circuits to accompany each individual pixel on the chip, and Grass Valley’s Weber described some coming advances there. “There are CMOS imagers that use a number of transistors for each pixel, the so-called 3T, 4T and 5T imagers.” As the manufacturing processes continue to advance and it’s possible to pair more transistors with individual pixels, that T-number can be expected to increase.

This summer, an announcement from Japan by Fujifilm and Panasonic detailed a jointly-developed “organic CMOS image sensor technology that uses an organic photoelectric conversion layer with a photoelectric conversion property at the light receiving section of an image sensor to achieve performance beyond that of conventional image sensors.” Increased dynamic range and sensitivity are among the touted advantages of this technology.

Asked to look into their professional crystal balls for a sensor technology that could relegate CMOS to its own museum display case, none of those interviewed for this article saw anything coming down the development road. As JVC’s Shane put it: “There might be something in the labs, but it’s not something that’s visible and that we can see in the future.”

To borrow from an old Virginia Slims commercial, in the 10 years since CMOS cameras made their NAB Show debut, “You’ve come a long way, baby.”