Converting to digital III

As the DTV transition nears, many stations will look to reuse as much of their RF components as possible to save on costs. While each station should consult with their equipment manufacturers and/or professional RF engineer to ascertain what is possible, following is a description of how public broadcaster KMTP out of San Francisco is planning its own conversion. In the last tutorial, the issues of converting an analog UHF TV transmitter were discussed, as were the challenges faced by KMTP. This tutorial will cover the RF components involved in connecting the backup DTV transmitter to the antenna.

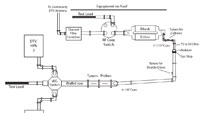

RF switching and plumbing

In a typical full-power transmitter configuration, the first thing that happens is that the high-power amplifier (HPA) outputs go through a high-power filter to attenuate the second and third harmonics, which is almost always a ridge coax filter. In the case of KMTP, the filter on the original DTV HPA is of the correct frequency (Channel 33), but the converted analog HPA has a harmonic filter for Channel 32. According to the transmitter manufacturer, this filter will work fine with only a one channel change because the filter is a low-pass filter. (See Figure 1.)

Next, the two HPAs (the original DTV and the converted analog) will go to an RF switch — in this case, a waveguide switch where either can be directed to the antenna or station load. This switch is currently being used on the analog RF system. The station load port of the switch will have an extra waveguide section that contains sampling probes, so the signal to the load can be monitored. Again, the probe section and station load come from the analog RF system. Some RF loads are frequency dependent and will only provide a proper load on its frequency (check for a channel number imprinted on the load or check with the manufacturer).

The output of the switch will go to the waffle-iron filter, which is another harmonic filter that helps in meeting the FCC required attenuation of 110dBc of the second and third harmonics to keep them from interfering with GPS signals. After that come sampling probes and matching tuners before transitioning to ridge coax for the run up to the rooftop mask filter, switch gear and the antenna. (See Figure 2.)

The matching tuners are used in several places along the transmission path to reduce or eliminate impedance mismatches. These mismatches occur mostly at transitions such as elbows, and especially at double elbows. New coax elbows can be ordered with matching tuners built into them.

Again in an effort to save on construction materials, the station will reuse the original NTSC ridge coax and then connect to the existing DTV transmission line that goes up to the roof. This presents a problem because the NTSC line is 6-1/8in and 75Ω, whereas the DTV line is 3-1/8in and 50Ω. Also, the 6in line uses Marmon flanges, while everything else uses EIA. To connect these two lines, several adapters will be required, but fortunately there’s a place where the two lines will meet with about 30in separating them — more than enough room to fit the adapters. First, a 6-1/8in section with a Marmon flange will be cut to length, and an EIA flange will be soldered to the other end. Then, the inner adapter from 75Ω to 50Ω will be order to fit. Next will be a gas stop for pressurizing the line and then a reducer from 6-1/8in to 3-1/8in. A set of matching tuners will be added to the 3-1/8in line following these adapters.

Get the TV Tech Newsletter

The professional video industry's #1 source for news, trends and product and tech information. Sign up below.

The tuners can be as simple as a set of nuts soldered over carefully spaced holes in the ridge coax’s outer conductor. Then bolts are screwed in to affect the fields in the line and match the impedance, and a second nut is added to secure the bolt once it is positioned.

Power

Power and frequency are the factors when selecting transmission line. The 6-1/8in ridge coax will handle up to 73kW average power (at Channel 33), but the 3-1/8in is rated for only 22kW average, which is a problem because the DTV power required by KMTP is 21.73kW (almost 4kW above what the transmitter is producing now). The 3-1/8in coax was fine when the DTV transmitter was first put in because the mask filter would only handle 18kW of input power. But now the power requirement was increased when it was decided that the new community DTV antenna would provide vertical as well as horizontal polarization, which will assist in reception on mobile devices. The mix will be 500kW ERP on horizontal polarization and 100kW ERP vertical polarization creating an elliptical polarization. (See Figure 3.)

Instead of replacing the 3-1/8in line, it was decided (to save on cost) to pressurize it. At 15psi, the line will have its power capability increased by a factor of 1.21, or 26.62kW average power, giving the station a little more than 4kW of headroom, as it is now. A pressure switch will need to be added to shut off the RF in case of a pressure loss on this line, because now a loss in pressure could lead to damage of the transmission line. A gas stop will be put on the 6-1/8in side of the reducer to ensure that the reducer, as well as the 3-1/8in line, is pressurized. (See Figure 4.)

The average power carried by a transmission line determines the temperature of both the outer and inner conductor, but it’s the inner conductor that is of prime concern because its heat is trapped within the transmission line. By increasing the pressure within the transmission line, heat is more easily transferred to the outer conductor and dissipated, increasing the average power capacity. Another heat factor comes from exposure to the sun. A transmission line installed outdoors exposed to the sun increases its temperature and reduces its power handling capacity. All of these factors must be considered when planning a transmission system and its path — running a transmission line under anything that would protect it from the sun will aid in its power handling capacity.

Conclusion

At the end of all this construction, KMTP will have a professional RF engineer on-site to sweep the entire system and adjust the installed tuners before any power is applied to the system. And because several of the RF components are being reused, the temperature of the line, and especially the elbows, will be monitored closely. A single failed elbow can have a dramatic effect. (See Figure 5.) Stations that plan to perform these types of conversions right after Feb. 17 should line up an RF professional now, because they will be in short supply starting Feb. 18.

Have comments or questions about this article? Leave a comment below or visit our Forum to start a discussion.