On the road with HD

France 3’s OB truck, shown here in action at the Tour de France, employs twin Studer Vista 6 digital broadcast consoles.

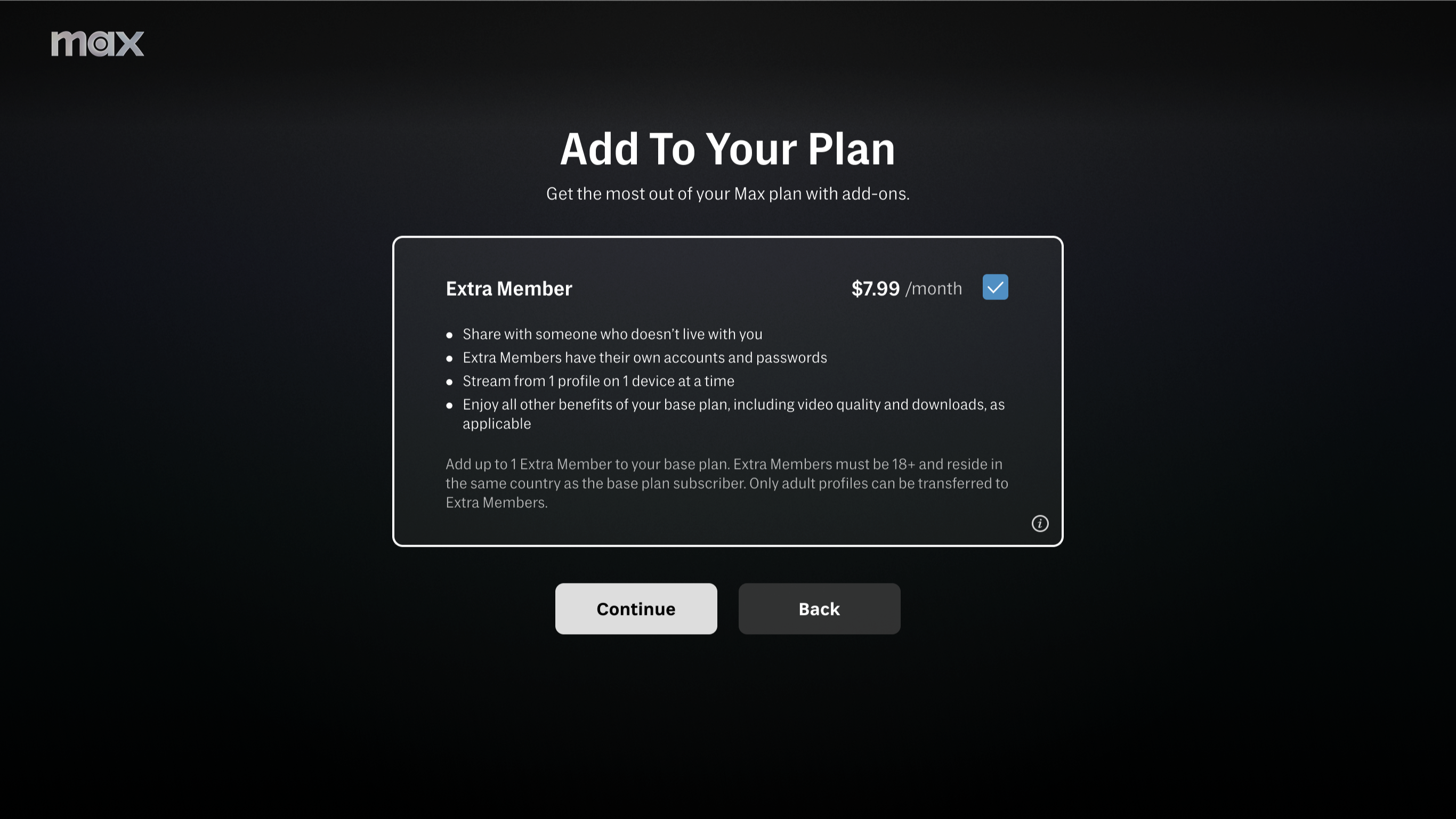

Europe is at that point where OB truck fleets have to be evaluated and upgraded to meet the demands of the new transmission format. This article looks at the issues involved and how smart design can maximize the financial return from these vehicles.

Multiformat

The big issue when buying a truck is the return on investment. Trucks are typically replaced on a rolling basis as they reach the end of their life. However, sometimes there is a step change in technology that demands the replacement of the fleet, and HD is one of those moments. Two factors greatly influence truck specification: operational space and dead time.

The companies booking trucks specify the number of crew required for the event. This means that operational space is of great importance when specifying a truck. Early trucks were often designed with lockers to carry cables, cameras and chairs, yet these can all be carried in a simple box van. An OB truck should be devoted to the operational requirements of the live production.

Dead time must be minimized. The truck should be designed for the shortest possible rig and derig time. Many factors contribute to this. As an example, designers have turned to automation for flexible reassignment of technical systems such as routers, intercoms and audio console configurations.

Chassis

Get the TV Tech Newsletter

The professional video industry's #1 source for news, trends and product and tech information. Sign up below.

Trucks in Europe have to be built within certain size and weight limits. An articulated truck with a semi-trailer can have a maximum length of 16m, including the tractor; the trailer will be less than 13.6m long and 12m from the kingpin to the rear. Rigids are shorter at 12m overall, with about 10m for the system.

The maximum width is 2.55m for both configurations, with a height of 4m. If expanding sides are used, then the truck can be extended about 1m on each side to a total working width of about 4.5m.

The maximum weight of a trailer is about 30 tons; the rest of the weight is made up by the tractor. Of those 30 tons, perhaps 4.5 tons are the technical equipment; the rest is made up by the chassis, coachwork and air conditioning.

The choice between a rigid or articulated truck often comes down to the personal preferences of the broadcaster. Some folks like rigids because you can jump in and go. The tractor/semi-trailer, though, has many advantages. It is much more maneuverable using the swing around the kingpin, which is important for getting into awkward venues. Some trailers even have rear wheel steering, a boon for squeezing into tight spots.

Perhaps the biggest advantage of the articulated approach is that the tractor can be taken away for maintenance and another used. If the engine of a rigid needs to go into the shop for maintenance, then the entire production system will be out of commission. A trailer may also outlive the tractor unit, therefore extending the useful life of the technical systems.

Video

The video system of the truck comprises fixed equipment — the switcher and router — plus demountable VTRs. That way, the trucks can be quickly fitted with the appropriate VTR format for the job.

The move to HD has not had a great impact on the video system; an HD router is physically no larger than an SD one. The main area of change in modern trucks has been in monitoring. The demands started to change even in SD with the move to a 16:9 aspect ratio. When shooting HD, the producer needs to get a better view of the picture, so the angle subtended to the eye by the primary monitors needs to be greater. That way, he or she can check for issues that show up in HD but were not a problem with SD.

Old SD trucks typically used 20in monitors; HD applications often require a 32in display for critical viewing. Thus, the requirements of widescreen and HD both demand displays with a larger diagonal. Luckily, high-quality LCDs have arrived, saving both weight and space (with their shallow depth).

For maximum flexibility, trucks have always had comprehensive patch bays. In addition, it is now common to include a large router, as this can speed reconfiguration of the truck for different applications. It is commonplace to fit a 512 square router chassis in a 24-camera truck. It may not have all the inputs loaded, but the demands of monitoring and clean feeds can quickly use up those extra outputs.

When HD first started, the big question was whether to build 720p or 1080i, as both cameras and switchers supported only one format. Now, much of the equipment is switchable, so that problem has gone away.

Most trucks will have CGs and slow-motion equipment built-in, but rack space needs to be allocated for a producer's favored graphics equipment. These devices will be rigged for each outside broadcast.

A truck can hold about 20 personnel. Some complex sports events will call for 30 or more to cater for graphics, special feeds and iso recording. So, although the modern truck can handle most sports or music events as a stand-alone, key events may dictate a VTR truck or a graphics truck be added to provide additional capability.

Audio

The audio system centers on the mixer. Hand-in-hand with HD is the requirement to mix 5.1 or 7.1 surround sound. Most audio mixers can be supplied with 5.1 options fitted; the challenge is monitoring surround in the confines of a truck.

There are many more considerations to be made when choosing an audio mixer for installation in an OB truck rather than a studio, with reliability and robustness at the top of the list. The console not only has to withstand extreme transportation conditions on a continuous basis, but also it must be guaranteed to work wherever the truck may be.

Second, physical space requirement is one of the biggest issues. Fortunately, digital consoles offer sophisticated functionality with a smaller control surface. The challenge for console manufacturers is to offer a more ergonomic and faster-to-operate user interface than an analog console and in a much smaller space.

It is not only the size of the control surface but also the associated rack electronics that affects space and weight considerations. This is particularly critical when it comes to replacing an existing analog console. The existing rack electronics space is usually minimal. Therefore, the available space for a new digital mixer is limited. Unfortunately, digital mixers often require more rack space than do older analog consoles. What typically takes the rack space in this case is the analog outboard gear, which, with a digital console, sometimes can be completely removed if these features are part of the console.

An OB truck must be able to handle different kinds of audio production-without compromise. The requirement of the mixer for a sports event, for instance, is completely different than that of a music festival. For a sports event, many inputs, mix minus functionality and special audio-follows-video functionality are the key requirements of the desk. For a music festival, multi-track capability combined with in-channel processing and even dynamic automation for fixing live-to-tape broadcasts becomes a priority.

The desk needs to be ergonomic with a familiar control surface so it's easy to use by the freelance engineering community. An engineer may be sitting at the desk for the first time mixing the Winter Olympics or World Cup!

In the instance of a combined video/audio truck, system integration is important. By design, a digital audio mixer also has an integrated audio router. If this router can be used as the audio layer of the video router, then this will not only be space-saving, but also it could offer large cost savings. For this to work, part of the audio console router must be controllable by the video switcher.

Other system integration issues include the decision whether or not to use stageboxes with optical MADI connections or continue to use long analog multicore cable runs. One advantage in using the optical solution is that all earth loop issues are removed. The PA console operators will be extremely happy when they see optical fibers being run from the stage to the truck. Another advantage is that an audio fiber snake can be set up in a fraction of the time of multiple connectors, resulting in a shorter rig time.

Comms and power

The buzz word for communications is IP. Phones and talkback can all be integrated with an IP infrastructure. Talkback systems can use a matrix approach, and most intercoms can service up to 128 ports.

A large truck may consume 20kW for technical equipment, with another 20kW for air conditioning in hot weather. This is usually sourced from the site's fixed supply, although generators may be required at remote sites. The technical supply will use a voltage regulator to smooth out voltage variations.

I would like to acknowledge assistance from Jamie Dunn at Studer in preparing this article.