Coefficients for Acoustical Materials

Whether it’s audio, video, post, or editing, one aspect of good control room design involves the proper use and placement of acoustical materials, primarily absorbers and diffusors, and sometimes reflectors as well. Selecting the appropriate materials is helped by product specifications.

ABSORPTION COEFFICIENT

The design team for Discovery’s new audio edit suites in its Silver Spring, Md. headquarters used a combination of different diffusion and absorption materials to minimize detrimental reflections.

There are standards that describe how to measure and calculate these parameters. ISO 354 covers the absorption coefficient, while ISO 17497-1 and ISO 17497-2 address the scattering coefficient and diffusion coefficient, respectively. In addition, the AES information document for room acoustics and sound reinforcement systems, AES-4id-2001 (r2007) describes the “characterization and measurement of surface scattering uniformity.” These types of tests are generally conducted in labs designed for acoustical measurements.

The absorption coefficient indicates how much randomly incident sound energy is absorbed. Ideally this number is given for different frequency bands, such as one octave or one-third octave, because materials tend to have different absorption characteristics at different frequencies. Absorption coefficients range between zero and one, with zero being totally reflective and one being totally absorptive. The higher the number, the greater the sound absorption. An absorption coefficient of 0.6, for example, means that 60 percent of acoustical energy hitting that surface will be absorbed, and 40 percent will be reflected or scattered.

Sometimes we’ll see an absorption coefficient greater than one, and that can result from such factors as the size of the material being tested, the frequency range, the edge effect of additional absorption from exposed edges, the formula being used for calculations and the use, or not, of a reference reflector in the measurement protocol.

One method of determining the absorption coefficient involves making measurements in a reverberation room. The idea is to compare the measurement of the reverberation time of the room with and without the absorbing material. The reverberation time is usually derived from an impulse response measurement and is the time it takes for sound to decay 60 dB after a sound source is turned off. With absorption in the room, the reverb time should be less than that of an empty room. Many measurements are generally taken and averaged.

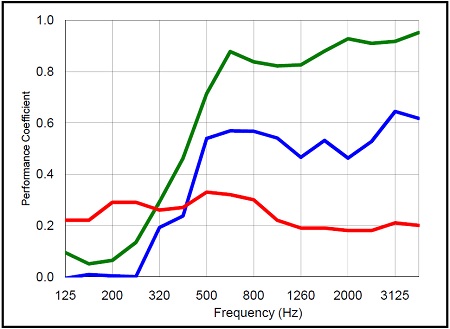

Fig. 1: To represent acoustical data, RPG Diffusors provides graphs with absorption, scattering, and diffusion coefficients plotted against frequency.

Other parameters, like room volume and air temperature and attenuation—which affect the speed of sound—are also measured. All of these are cranked through formulas to come up with the absorption coefficient (absorption per unit area).

The procedures for obtaining the absorption coefficient have come under review as standards for the scattering and diffusion coefficients were being developed. The value of the absorption coefficient can vary depending on the lab conducting the test and the nature of their reverberation room. Not all rooms are uniformly and totally diffuse; there are differences in what types of diffusing elements are installed and where they are placed within the room. There can also be differences in how the test materials are mounted and the attention given to the edge effect.

There has been a good argument for using a purely reflective surface as a calibration material, instead of the empty room, for the base measurement since both the reflector and absorber will be measured under the same room conditions. Also, a different formula than is commonly used for calculating the absorption coefficient seems to better indicate what the absorption will be when the material is actually installed in a control room.

These are some of the things to be aware of when looking at absorption coefficients and comparing materials. You may have to specifically ask the manufacturer for this level of detail and information on how the tests were conducted. Don’t overlook differences in absorption depending on how the material is mounted.

SCATTERING AND DIFFUSION COEFFICIENTS

Since the commercialization of diffusing products—pioneered by RPG Diffusors—is fairly recent (early 1980s), a standard approach to measuring and calculating the scattering and diffusion coefficients is also quite recent, having undergone many iterations in development.

When sound hits a diffusive surface, what isn’t absorbed is reflected back at many different angles (spatial diffusion). The reflections also can arrive at a listener at different times (temporal diffusion), and in that case absorption should be minimal. By comparison, a reflective surface follows the rule of specular reflections that the angle of incidence equals the angle of reflection. A diffuser, by definition, shouldn’t concentrate its scattered sound in the specular zone.

Diffusive materials differ in how they scatter sound. Some scatter sound in a way that favors certain angles and not others. This could be considered a poor diffusor since the sound is not scattered in a uniform way, even though it scatters sound away from the specular zone. A good diffuser scatters sound more evenly in both space and time.

This brings up the difference between the scatter and diffusion coefficient. The scatter coefficient indicates how much sound energy is scattered away from the specular zone. It doesn’t indicate anything about how evenly the scattered sound is distributed. According to the ISO standard, the scattering coefficient can only be measured on material that has an absorption coefficient less than 0.5.

The diffusion coefficient, on the other hand, indicates the uniformity of the scattering. The value of either of these coefficients ranges from zero to one. The greater the value, the greater the amount of scattering or uniformity of diffusion, depending on which coefficient we’re talking about.

MEASURING COEFFICIENTS

These coefficients can be derived by measuring the polar responses and comparing those of a reflective surface to the diffusive surface under test. A source loudspeaker emitting a specific test signal is aimed at a certain angle at the diffuser or reference reflector. Random incidence measurements can also be made.

The sound energy coming off the device under test is measured at multiple angles around the material. In practice, to reduce the measurement time, multiple microphones are placed on a boundary surface (like a floor) in a hemispherical arc pattern, with their signals simultaneously recorded. The next steps involve signal processing and computations to derive the coefficients.

Unlike the measurement of absorption coefficients which requires a reverberation room, measurements of the scattering and diffusion coefficients need to be measured in a room where any surface reflections don’t enter the measurements. This could be an anechoic chamber or a very large room with a reflection-free zone surrounding the test setup. Because of the size of some diffusor arrays, it can be difficult to find an appropriate measurement space.

The folks at RPG addressed this issue by developing testing methods that can use accurate scale models of the diffusors under test, with the diffusors placed on a boundary surface. The test signals need to be scaled up in frequency and the loudspeaker emitting the test signals and the measuring mics need to have appropriate frequency and phase responses at these frequencies. This allows measurements to be made in a more practical-sized space, with a smaller reflection-free zone needed around the test setup.

As an example of one manufacturer’s approach to presenting acoustical data, RPG provides graphs with absorption, scattering, and diffusion coefficients plotted against frequency (Fig. 1). They also provide tables with the coefficient values for each frequency band. In addition they often show a picture of the test setup.

When choosing acoustical materials, look for the test data on absorption, scattering and diffusion by frequency band, and ask manufacturers if you can’t readily find it.

Mary C. Gruszka is a systems design engineer, project manager, consultant and writer based in the New York metro area. She can be reached via TV Technology.

Get the TV Tech Newsletter

The professional video industry's #1 source for news, trends and product and tech information. Sign up below.