New graphene sensor holds promise of better low light images, lower cost

Graphene, an allotrope of carbon, may be the key to extremely low light images and lower costs in all types of cameras. It makes up a new image sensor developed at the Nanyang Technological University (NTU) in Singapore that is said to be 1000 times more sensitive to light than traditional sensor technology.

The new sensor made from graphene is believed to be the first to be able to detect broad spectrum light, from the visible to mid-infrared, with high sensitivity, reported Science Daily. This means it is suitable for use in all types of cameras, including video, still, infrared, traffic speed devices and satellite imaging.

Not only is the graphene sensor far more sensitive to light than in current imaging technology, it also uses 10 times less energy as it operates at lower voltages. When mass-produced, graphene sensors are estimated to cost at least five times less.

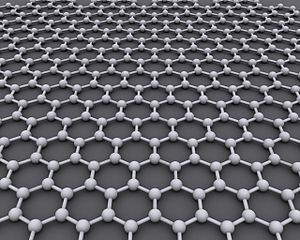

NTU said graphene, the world’s hardest material (tougher than diamonds) is a million times smaller than the thickest human hair (only one-atom thick) and is made of pure carbon atoms arranged in a honeycomb structure. It is known to have a high electrical conductivity among other properties such as durability and flexibility.

The inventor of the graphene sensor, Wang Qijie, assistant professor at NTU’s School of Electrical & Electronic Engineering, said it is believed to be the first time that a broad-spectrum, high photosensitive sensor has been developed using pure graphene.

“While designing this sensor, we have kept current manufacturing practices in mind,” Wang said. “This means the industry can in principle continue producing camera sensors using the CMOS process, which is the prevailing technology used by the majority of factories in the electronics industry. Therefore, manufacturers can easily replace the current base material of photo sensors with our new nano-structured graphene material.”

Wang devised the idea to create nanostructures on graphene that would “trap” light-generated electron particles for a much longer time, resulting in a much stronger electric signal. Such electric signals could then be processed into an image, such as a photograph captured by a digital camera.

The “trapped electrons” are the key to achieving high sensitivity in graphene, which makes it far more effective than the normal CMOS or CCD (charge-coupled device) image sensors, Wang said.

“The performance of our graphene sensor can be further improved, such as the response speed, through nanostructure engineering of graphene, and preliminary results already verified the feasibility of our concept,” Wang added.

Development of the new sensor took Wang two years to complete. His team consisted of two research fellows, Dr. Zhang Yongzhe and Dr. Li Xiaohui, and four doctoral students Liu Tao, Meng Bo, Liang Guozhen and Hu Xiaonan, from EEE, NTU. Two undergraduate students were also involved in the ground-breaking work.

Wang has filed a patent through NTU’s Nanyang Innovation and Enterprise Office for his invention. The next step is to work with industry collaborators to develop the graphene sensor into a commercial product.

Get the TV Tech Newsletter

The professional video industry's #1 source for news, trends and product and tech information. Sign up below.